In the healthcare industry, the need for effective sterilization of medical devices and equipment is paramount. Ethylene oxide (ETO) sterilizer machines have emerged as a reliable solution for achieving high-level disinfection. These machines offer multifunctionality, making them a versatile choice for various sterilization needs.

The Working Principle of ETO Sterilizer Machines

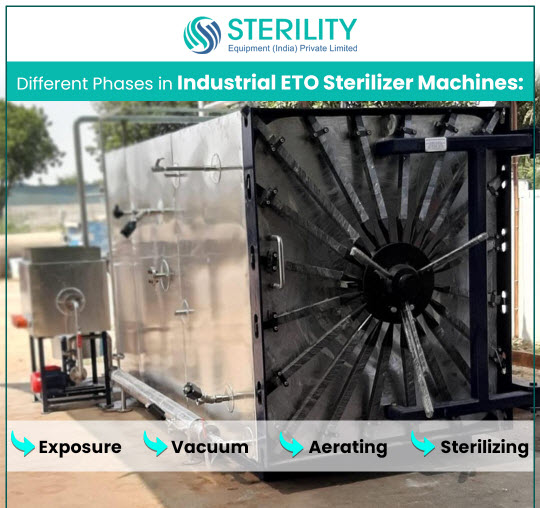

Industrial ETO sterilizer machines operate based on a few key principles. Firstly, the items to be sterilized are placed inside a sealed chamber. The chamber is then filled with a precise mixture of ethylene oxide gas and other sterilant additives. The machine creates a controlled environment where the gas concentration, humidity, and temperature are carefully regulated to ensure optimal sterilization conditions. The ethylene oxide gas penetrates the packaging and effectively kills microorganisms, including bacteria, viruses, and spores. After the sterilization cycle is complete, the gas is removed from the chamber, and the items are aerated to eliminate any residual gas.

Advantages of ETO Sterilizer Machines

ETO sterilizer machines offer several advantages that make them a preferred choice in various industries. Firstly, they provide excellent penetration and can reach inaccessible areas of complex medical devices and equipment, ensuring thorough sterilization. Additionally, the low-temperature sterilization process of ETO machines makes them suitable for sensitive materials that cannot withstand high-temperature sterilization methods such as autoclaving. Moreover, ETO sterilization is compatible with a wide range of materials, including plastics, metals, glass, and rubber. This versatility enables the sterilization of diverse medical devices and equipment.

Sterilization of Medical Devices

One of the primary applications of ETO sterilizer machines is in the healthcare industry for the sterilization of medical devices. These machines are capable of sterilizing a wide array of devices, including surgical instruments, catheters, implants, and diagnostic equipment. The ability to penetrate complex instruments makes ETO sterilization an ideal choice for delicate and intricate medical devices.

Pharmaceutical Industry

The pharmaceutical industry heavily relies on ETO sterilizer machines for the sterilization of pharmaceutical products and packaging materials. ETO sterilization ensures the removal of microbial contaminants from packaging materials, maintaining the integrity and safety of pharmaceutical products. ETO sterilization is particularly useful for heat-sensitive pharmaceuticals and materials that cannot withstand high-temperature sterilization methods.

Laboratory Equipment

In research and diagnostic laboratories, ETO sterilizer machines are widely used for the sterilization of laboratory equipment. Glassware, pipettes, Petri dishes, and other reusable lab instruments can be effectively sterilized using ETO. This helps prevent cross-contamination and ensures the accuracy and reliability of laboratory results.

Food Processing Industry

The food processing industry also benefits from the multifunctionality of ETO sterilizer machines. These machines are employed to sterilize packaging materials, such as food containers and wrappers, ensuring the safety and extended shelf life of food products. ETO sterilization eliminates harmful bacteria and pathogens, minimizing the risk of foodborne illnesses.

Cosmetics and Personal Care Products

ETO sterilizer machines find applications in the cosmetics and personal care industry as well. They are used to sterilize packaging materials and containers for cosmetics, skincare products, and toiletries. ETO sterilization helps maintain product integrity and prevents microbial contamination, ensuring consumer safety.

Safety Considerations for ETO Sterilization

While ETO sterilizer machines offer numerous benefits, it is important to address safety considerations associated with the use of ethylene oxide gas. Ethylene oxide is a toxic and potentially hazardous substance. Therefore, proper ventilation systems, monitoring equipment, and safety protocols must be in place to protect operators and prevent exposure to ETO gas.

Factors Influencing the Effectiveness of ETO Sterilization

Several factors can influence the effectiveness of ETO sterilization. These include the gas concentration, exposure time, temperature, humidity, and compatibility of materials with ethylene oxide. It is crucial to follow manufacturer guidelines and validated protocols to ensure the desired level of sterilization is achieved consistently.

Factors Influencing the Effectiveness of ETO Sterilization

Several factors can influence the effectiveness of ETO sterilization. These include the gas concentration, exposure time, temperature, humidity, and the compatibility of materials with ethylene oxide. It is crucial to follow manufacturer guidelines and validated protocols to ensure the desired level of sterilization is achieved consistently.

The Future of ETO Sterilizer Machines

The field of sterilization continues to advance, and ETO sterilizer machines are evolving to meet the changing needs of industries. Ongoing research aims to improve the efficiency and safety of ETO sterilization processes while minimizing the environmental impact. Innovations in sterilizer designs, gas monitoring technologies, and alternative sterilization methods are being explored to enhance the overall performance of ETO sterilizer machines.